At Vidriera del Cardoner S.A. we are committed to innovation and we believe in the continuous work of research anb evolution to develop new products and improve day by day, to meet the continuous changes in the needs of the market.

We have highly versatile installations, and with the experience of our team in the sector it makes us particulary efficient in customizing and innovating our industrial production service.

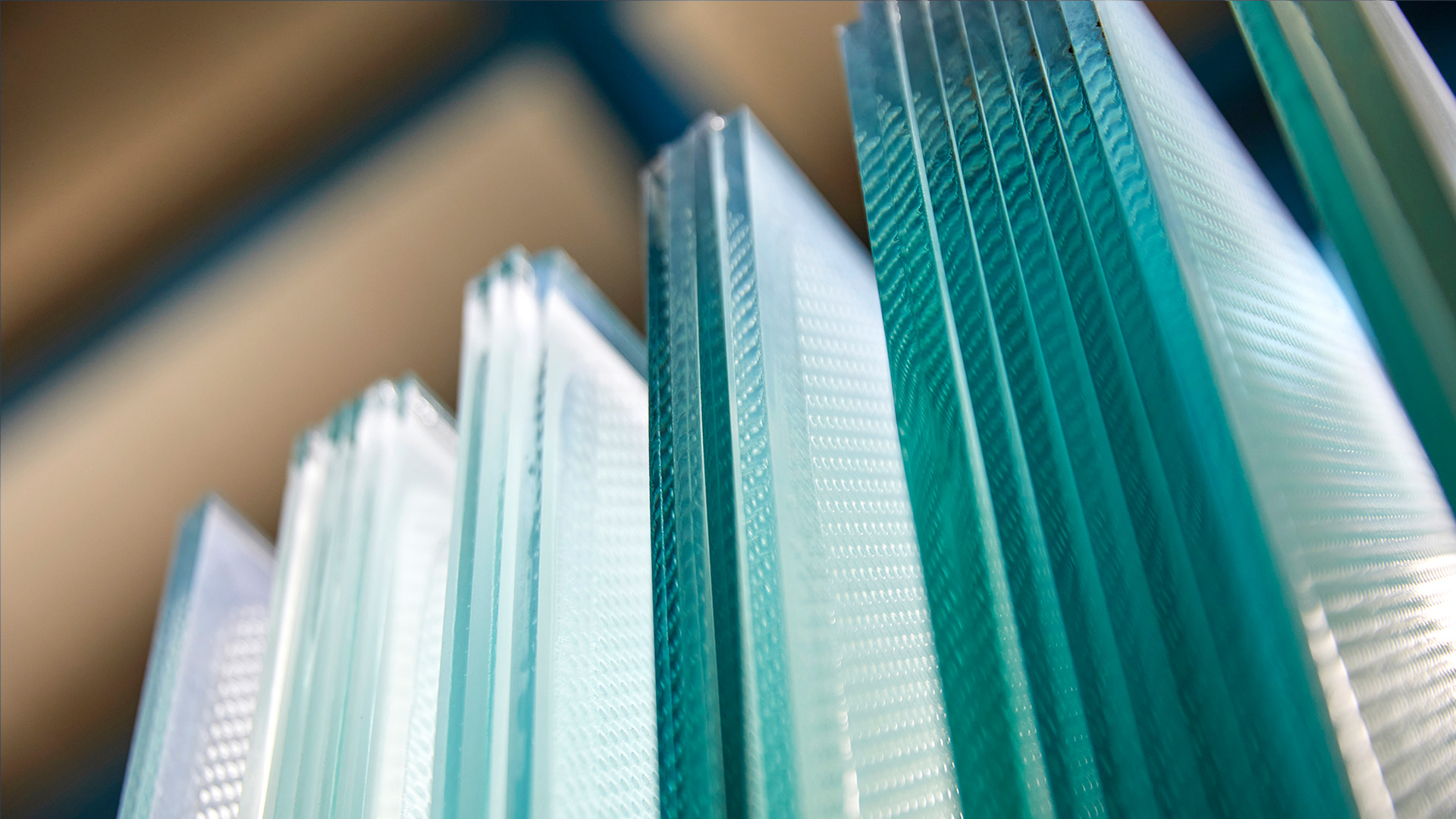

Thanks to the various manufacturing techniques and their combinations, we can offer and develop together with our customer multiple product possibilities.

Feel free to contact us to evaluate which is your best option.

Etched glass is a chemical process where the glass is attacked superficially on one of its sides to obtain various opacities with a satin appearance and different sensitivities to the touch. So that you can find the product that best suits your application needs.

Engrave is a chemical process of deep attack on the surface of the glass. Our different engraving depths offer a wide range ofter beautiful textures with the light comes through.

With this technique we can compose attractive designs by combining shapes and textures that give rise to a wide range of application possibilities.

The characteristic of our company of the process of glazing the glass is using screen printing with vitrifiable inorganic enamels and subsequent vitrification.

This process allows the manipulation of the glass before it. After the process you also can cut, polish the glass or carry out subseqüent safety treatments, to reach the desired application.

The lamination process is a treatment applied to the glass to give it maximum security once installed.

It consists of joining two sheets of glass with a thin sheet of butyral (pvb), which, in case of breakage, it will prevent the movement of glass pieces that make it up.

All our glass sheets allow this treatment and in certain locations it’s indispensable for their location.

The template process is a heat treatment of the glass to give it hardness and safety.

This is a sudden heating and subsequent cooling of the glass that changes its internal structure, hardening it to make it more difficult to break, and if it breaks, it will do so in small parts to avoid damage.

All our products allow this security treatment.

Accessibility Tools